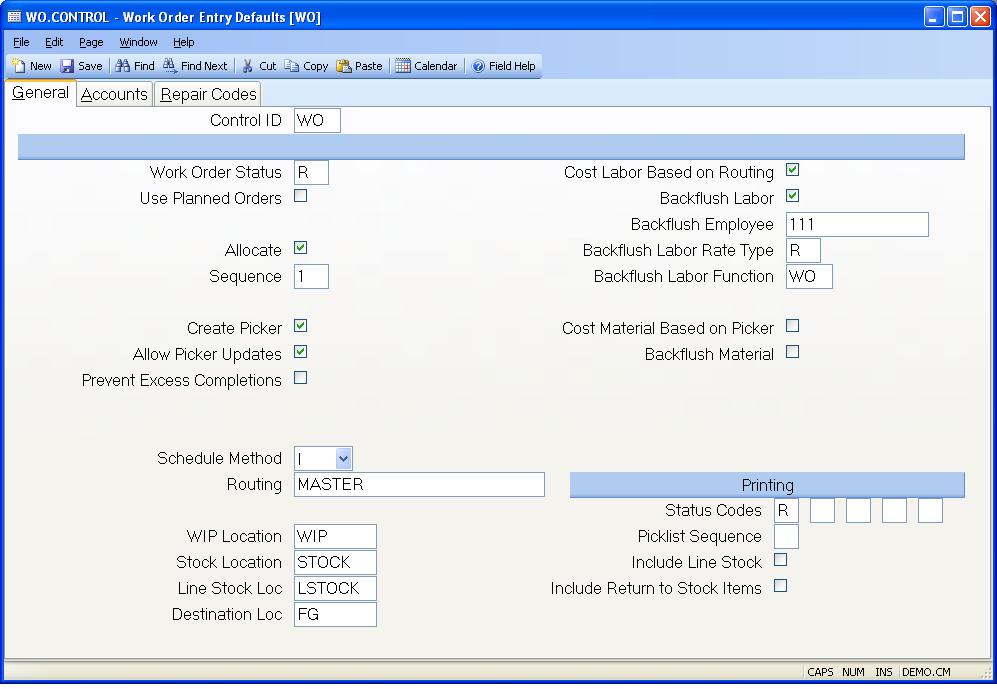

# Work Order Entry Defaults (WO.CONTROL)

Read Time: 5 minute(s)

# General

Control ID The ID to this record is "WO" and is automatically loaded by the system.

Work Order Status Enter one of the following status codes:

N - New work order

O - Open work order

R - Release work order The code entered will be used as the default status

during work order entry.

Use Planned Orders? Check this box if you want to create work orders from planned orders. Planned order information will be presented for selection, and if selected will cause work order information to be defaulted from the planned order.

Allocate? Check this box if the default entry for allocating components is to be yes. Otherwise, leave this box unchecked.

Allocation Sequence Enter one of the following numbers which defines the

method used for automatically allocating lots for components on the pick list:

0. Do not automatically assign lot numbers.

1. Use oldest lots first regardless of available quantity.

2. Use the lot that has the smallest available quantity that still meets the

quantity required. Unless you have parts that are lot controlled you should

always set this field to 0.

Create Picker? Check this box if a picker record is normally created.

Allow Picker Updates Check this box if updates to the part number and location fields are allowed in PICKER.E2 . If this box is not checked, you will need to use PICKER.E1 to make those changes.

Prevent Excess Completions Check this box if a work order cannot be completed for a quantity greater than what is was issued for. If this box is checked and the status on the work order was manually changed to "C" (for completed), you will not be able to make any additional completions against the work order.

Field6 Enter one of the following three codes to define the default

schedule method to be used:

F - Schedule order based on available capacity.

I - Schedule based on routing only without checking available capacity.

M - Manually schedule the order.

Routing Enter the default routing to be loaded when there is no routing on file for the part number on the order.

WIP Location Enter the ID of the work in process location to be used.

Stock Location Enter the location from which material is to be pulled.

Line Stock Location Enter the location from which line stock will be pulled.

Destination Location Enter the default location to be used as the destination location for work order entry.

Labor by Routing If your inventory costing method is set to average or actual cost (see INV.CONTROL ), you have the option of letting the system calculate the value of labor for the items built based on the hours in the work order routing instead of the actual hours posted through labor transactions. This option may be appropriate if you do not plan to post labor transactions or if you make partial completions from a work order. Variances between the actual labor posted and the routing labor will be posted when the work order is finalized.

Backflush Labor If you do not post labor transactions to work orders, you may have the system post labor automatically based on the routing by checking this box. As items are completed labor transactions will be created based on the hours specified in the work order routing.

Backflush Employee Enter the employee number to be used on labor transactions created when labor is backflushed.

Backflush Labor Rate Type Enter the labor rate type code (defined in LABOR.CONTROL ) to be used when labor transactions are created by the labor backflush process.

Backflush Labor Function Enter the labor function to be used when labor records are created for backflushed labor.

Material by Picker If you check this box the value of material for items completed from the work order will be based on the value of the items in the picker. This only applies when the inventory costing method is average or actual (see INV.CONTROL ). This can be useful in cases where all of the materials are not moved into the work order before completions are made. This avoids having earlier completions carrying a lower material value than later completions. It also prevents the presence of excess materials or deficits of material from affecting the value.

Backflush Material Check this box if the default setting for new work orders should be set to backflush.

Status Codes Rather then print, or be asked the question to print the

various work order documents each

time the work order is saved, it may be desirable to limit this to times when

the work order is in

one or more specific states. You may do this by entering each of the status

codes at which

you want this to occur. Possible entries are:

N - New

O - Open

R - Released

P - Pulled

C - Closed

F -

Picklist Sequence Enter the letter "B" if the items on the pick list are to be sorted in bin number sequence, "P" if the are to be sorted in the default picklist sequence, or "R" if the sort should be done based on reference bin location.

Include Line Stock Check this box if line stock items are to be included in the printed picking list.

Include Return to Stock Items Check this box if line return to stock items are to be included in the printed picking list.

Version 8.10.57