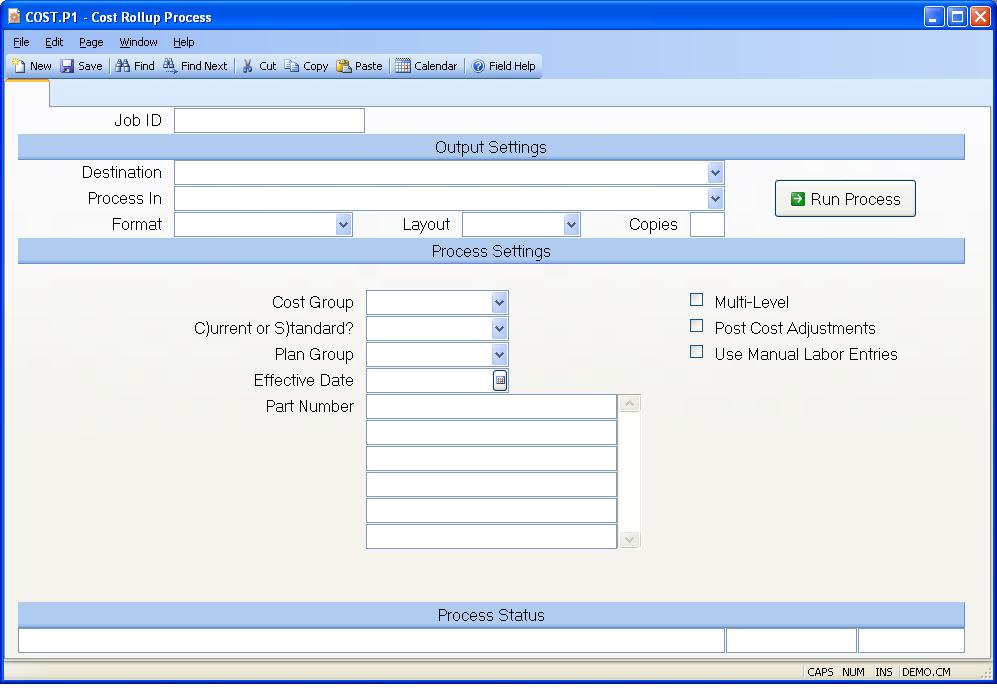

# Cost Rollup Process (COST.P1)

Read Time: 4 minute(s)

#

Job ID Enter a unique ID if you wish to enter and save the parameters to this procedure for future use. If you only need to run the procedure and do not want to save your entry then you may leave this field empty.

Destination Select the destination for the output from this procedure.

Process Select the method to be used for processing the report. Foreground is always available and must be used when output is directed to anything other than a system printer (i.e. printers spooled through the database on the host computer.) Depending on your setup there may be various batch process queues available in the list that allow you to submit the job for processing in the background or at a predefined time such as overnight. A system printer must be specified when using these queues.

Format Select the format for the output. The availability of other formats depends on what is allowed by each procedure. Possible formats include Text, Excel, Word, PDF, HTML, Comma delimited and Tab delimited.

Layout You may indicate the layout of the printed page by specifying the appropriate setting in this field. Set the value to Portrait if the page is to be oriented with the shorter dimension (usually 8.5 inches) at the top or Landscape if the longer dimension (usually 11 inches) is to be at the top. Portrait will always be available but Landscape is dependent on the output destination and may not be available in all cases.

Copies Enter the number of copies to be printed.

Run Process Click on the button to run the process. This performs the save function which may also be activated by clicking the save button in the tool bar or pressing the F9 key or Ctrl+S.

Cost Group Enter the cost group which will be validated against INV.CONTROL . The cost group is used to define the costing method and to group inventory locations together for averaging the cost within those locations.

Current or Standard Cost You have the option of rolling up either the current costs or the standard (book) costs. In the normal flow of operations you would rollup only current costs and then use the cost rollover procedure to move those costs to the standard fields when appropriate. Rolling up the standard cost fields is generally done only when a new item is added to the product line and production on the item is to begin prior to the next formal cost rollover.

Plan Group Enter the planning group that should be used in this process. This procedures uses the routing and make/buy code entered in PARTS.E to calculate the labor and material that should be applied to this part. These fields are defined by planning group in PARTS.E . Therefore, if more than one planning group has been set-up for this account, the program needs to know which planning group should be used in this procedure. If no entry has been made into this field, COST.P1 will use the data associated to the first planning group entered into PARTS.E .

Effective Date Enter the date to be used for the bill of material effectivity date. Bill of material line items will be included or excluded based on the start and end effectivity dates for each item relative to the date entered.

Part Number If you want to rollup all of the part numbers then leave this field blank. If you want to rollup specific assemblies then enter the part numbers of those items in this field. If the assembly has subassemblies, be sure to check the multi-level rollup option to include costs for the entire BOM structure.

Multi-level? If the cost rollup is being done for a specific assembly part number and you want a multi-level cost rollup, then check this box. If a rollup is being done for all part numbers, then this doesn't apply since it will already be doing a multi-level rollup.

Cost Adj Check this box if the adjustments resulting from the cost rollup process are to be posted to the inventory register. Otherwise leave unchecked. This option is only valid when rolling up standard cost group.

Last Status Message Contains the last status message generated by the program.

Last Status Date The date on which the last status message was generated.

Last Status Time The time at which the last status message was generated.

Use Manual Labor Entries Check this box if you wish to include the labor amount entered in COST.E in the rollup. Please note, that this option will only apply if a routing is not found for the part. If a routing is found, the labor amount will be based on the routing and the manual entry made in COST.E will be replaced with the calculated amount. Also, if this box is not checked and no routing is found for the part, the labor amount entered in COST.E will be deleted and the labor will not be included in the rollup.

Version 8.10.57