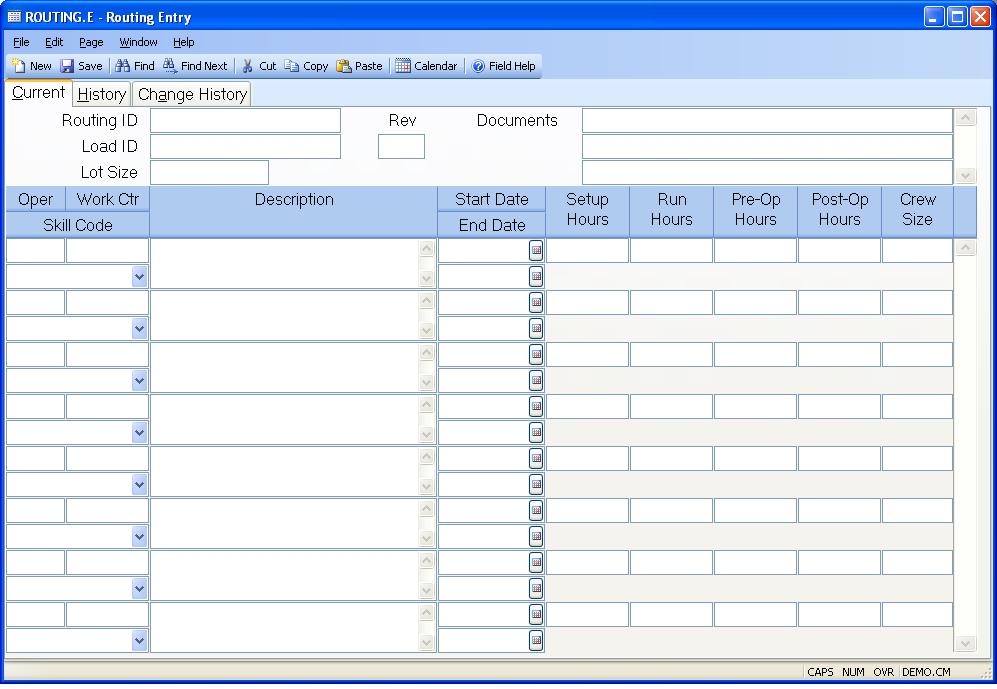

# Routing Entry (ROUTING.E)

Read Time: 3 minute(s)

# Current

Routing ID Enter the ID of the routing you want to add or update. Routings may defined with any form of record ID desired, however those which are assigned the same number as an existing part number will automatically be used as the default routing when work orders are created for the part. If you enter a new ID which does not identify an existing part , you will receive a warning message stating this fact. It does not prevent you from using the ID entered.

Load Routing You may load an existing routing as the starting point for the current routing by entering the ID of the routing to be loaded in this field. This option is only permitted on new records.

Lot Size Enter the standard lot size used for this routing. The lot size is used as a means of scaling the run hours so that they reflect the number of hours required to complete the number of units specified by lot size. For example, if you have set the lot size to 100 and enter the run hours for a given operation to 3.50, you are saying that it takes 3.5 hours to complete 100 units at the operation, or .035 hours per unit (3.5 / 100). If no lot size is specified then 1 is assumed.

Rev Enter the current revision for the routing. If a change was made to the revision then the new revision will be added to the history list when the routing is saved or when you click on the history tab. You may add an effectivity date and description on the history tab if desired.

Documents Enter all of the documents that are associated with the current revision of the routing. These will appear on the work order traveler.

Operation Enter the operation number associated with the routing information defined.

Work Center Enter the work center at which the operation is performed.

Skill Code Select the skill code that applies to this operation. Skill codes are defined in the SKILL.CONTROL procedure and defines the skills an employee must have to perform the operation.

Description Enter a description and/or instructions which are associated with the operation.

Start Eff Date Enter the date on which the associated item is to become active. If no date is entered the item is assumed to be active.

End Eff Date Enter the last date on which the associated item is still active. After this date the item will no longer be active. A null entry indicates that the item has no expiration date.

Setup Hours Enter the hours required for setup before work can begin at the operation.

Run Hours Enter the number of hours required at the operation to complete the number of units indicated in the lot size.

Pre-Operation Hours Enter the number of hours for which materials are queued at the work center before work is started. This entry is defaulted from the Work Center file.

Post-Operation Hours Enter the number of hours that the materials wait and/or take to moved from the operation after completion.

Crew Size Enter the number of workers or machines normally used at the same time for this job.

Version 8.10.57