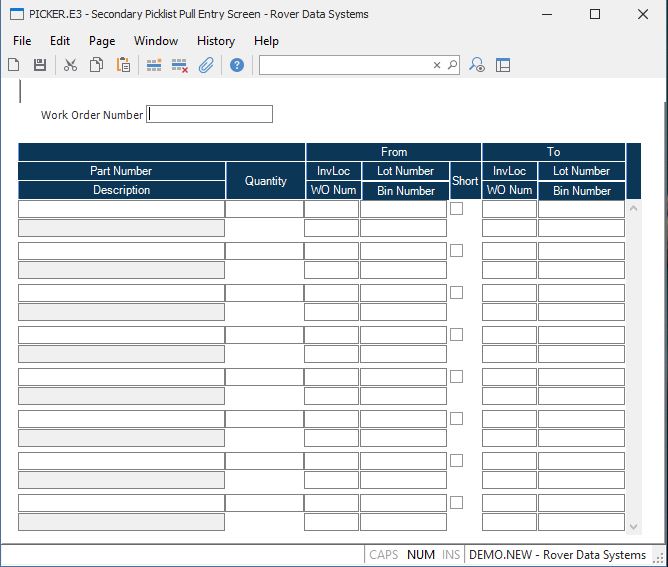

# Secondary Picklist Pull Entry Screen (PICKER.E3)

Read Time: 2 minute(s)

#

Transaction ID The inventory transaction number is assigned by system and does not appear as a prompt on the screen.

Work Order Number Enter the work order number you wish to process. All part numbers referrenced on the picklist that have not been pulled in full will be loaded into this screen for you. The quantity will be the difference between the quantity required and the quantity pulled and/or consumed. Please note that if the work order is scheduled to be backflushed, only parts that have an operation coded to "P" will be included. Once the parts are loaded into this screen, you can make whatever adjustments are required including deleting and adding part numbers.

Part Number Enter the part number of the item you are moving.

Description Contains the first line of the description from the PARTS file for the associated part number. The field is for reference only and may not be changed.

Quantity Enter the number of items being moved. After entry of the work order number, this field will be set to the difference between the quantity required for the referenced work order and the quantity consumed/pulled.

Loc Enter the location that the material is being moved from.

WO Enter the work order from which the item is being moved. An entry is required in this field only if the from location is a type "WO".

From Lot If the part number entered is lot controlled then enter the number of the lot being moved. You may leave this field blank if you are moving items in from a non-physical location and are creating a new lot number.

From Bin Enter the bin from which the material is being moved. This field is only prompted when the INVLOC record is set to bin control.

Qty Check this box if you wish to have a shortage posted against the work order for the quantity being removed. An entry in this field is required only if a from work order number is entered.

Loc Enter the location that the material is being moved to.

WO Enter the work order into which this item is being moved. An entry is required in this field only if the to location is a type "WO".

To Lot If the part number entered is lot controlled then enter the lot number the parts are being moved to. This entry will be defaulted to the same number entered in the from lot field. You may change it to another lot number if you are splitting the lot or consolidating items from one lot into another. If you leave this field blank it is assumed that you want the system to assign a new lot number.

To Bin Enter the bin to which the material is being moved. This field is only prompted when the INVLOC record is set to bin control.

Version 8.10.57