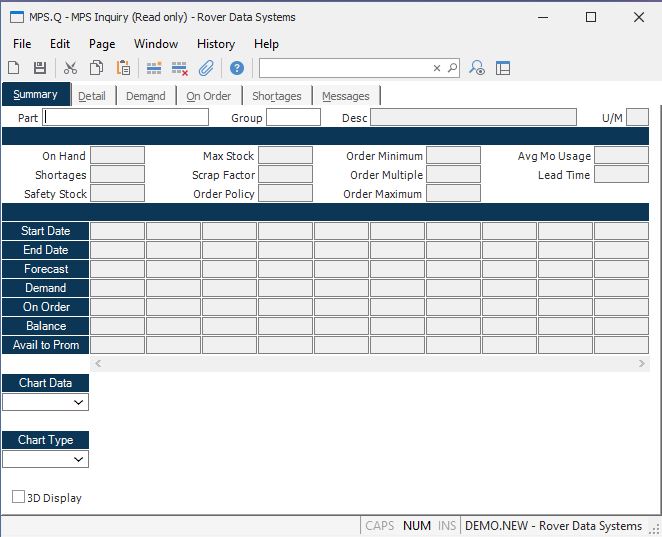

# MPS Inquiry (MPS.Q)

Read Time: 3 minute(s)

# Summary

Part Number Enter the part number of the item you want to display on the screen.

Group Enter the planning group you wish to display.

Description Contains the description of the part as entered in the parts master.

Unit of Measure Contains the stocking unit of measure for the part number entered.

On Hand Contains the inventory balance as it was at the time the MPS calculations were performed for this part number. The actual on hand balance may have changed since that time.

Shortages Contains the total number of the part which is short on work orders at the time the MPS was generated. This quantity may not match the total number of shortages shown on the shortage screen in this procedure since the contents of that screen are taken from the current data.

Safety Stock Contains the minimum quantity of inventory which should be maintained for the associated part. The initial on hand balance is reduced by this amount in the MPS calculations.

Max Stock Contains the maximum projected inventory balance which is allowed. Exceptions will be generated if this quantity is exceeded anywhere within the planning horizon.

Scrap Factor Contains the scrap factor to be applied to the gross requirements. The scrap factor is stated as the percentage of parts which are expected to be scrapped as a part of normal operations. This is also known as shrinkage. The system uses this factor to increase demand for the part by the anticipated shrinkage. The demand generated by the scrap factor will appear as an individual item in the pegging for the part.

Order Policy The order policy should be set to either "Fixed" or "Discrete". If no order policy has been specified then discrete is assumed.

Order Minimum Contains the recommended minimum order quantity for the associated part number.

Order Multiple Contains the recommended order multiple to be used when calculating order quantities.

Order Maximum Specifies the maximum quantity that should be ordered at one time.

Average Monthly Usage Contains the average monthly usage of the part based on the available transaction history.

Lead Time The number of days normally required to produce the associated part.

Period Start Date This field contains the start date for each period and the associated forecasts, requirements, receipts, projected balance and available to promise quantities for the period.

Period End Date This field contains the end date for each period and the associated forecast, requirements, receipts, projected balance and available to promise quantities.

Forecast Contains the forecasts for the part number which occur in the associated period.

Gross Requirments Contains the sum of all the requirements for the part number which occur in the associated period.

Scheduled Receipts Contains the sum of all purchase order receipts, planned completions from work orders and MPS items for the part number in the associated time period.

Projected Balance Contains the current projected on-hand balance less safety stock for the associated period.

Available To Promise Contains the quantity that is available to promise to customers until the next available quantity.

Chart Data Select the source of the data to be displayed in the chart.

Chart Type Select the format of the chart to be displayed.

3D Display Check this box if the chart is to be displayed in three dimensional format.

Chart Displays a chart of the data specified in the Chart Type prompt.

Version 8.10.57