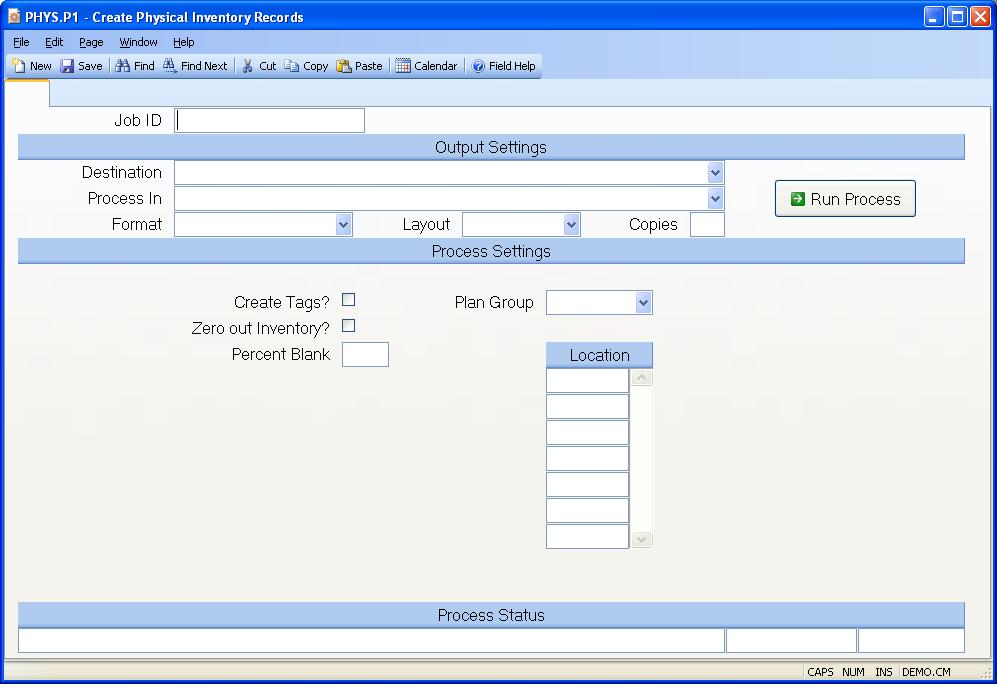

# Create Physical Inventory Records (PHYS.P1)

Read Time: 3 minute(s)

#

Job ID Enter a unique ID if you wish to enter and save the parameters to this procedure for future use. If you only need to run the procedure and do not want to save your entry then you may leave this field empty.

Destination Select the destination for the output from this procedure.

Process Select the method to be used for processing the report. Foreground is always available and must be used when output is directed to anything other than a system printer (i.e. printers spooled through the database on the host computer.) Depending on your setup there may be various batch process queues available in the list that allow you to submit the job for processing in the background or at a predefined time such as overnight. A system printer must be specified when using these queues.

Format Select the format for the output. The availability of other formats depends on what is allowed by each procedure. Possible formats include Text, Excel, Word, PDF, HTML, Comma delimited and Tab delimited.

Layout You may indicate the layout of the printed page by specifying the appropriate setting in this field. Set the value to Portrait if the page is to be oriented with the shorter dimension (usually 8.5 inches) at the top or Landscape if the longer dimension (usually 11 inches) is to be at the top. Portrait will always be available but Landscape is dependent on the output destination and may not be available in all cases.

Copies Enter the number of copies to be printed.

Run Process Click on the button to run the process. This performs the save function which may also be activated by clicking the save button in the tool bar or pressing the F9 key or Ctrl+S.

Create Tags? If you wish to create inventory tags for all inventory items with a quantity on hand, check this box. If this box is not checked, you will need to manually assign those tag numbers when entering in the physical counts. However, if you are using the standard trakker (scanner) procedures to count inventory, the tag numbers will automatically be assigned for you.

Zero out Inventory If this box is checked, inventory tags will be generated for all existing part numbers with a quantity on hand. These tags will be created with a count quantity of zero which will offset the existing quantity on hand.

Percent Blank Enter the percentage of blank tags to be created. If the inventories selected create 1000 physical tag records, and a percentage of 10 is entered, then an extra 100 blank tags will be created. If the create tags box is not checked, not blank tags will be generated.

Plan Group Enter the plan group for which you are creating physical tags.

Inventory Locations The inventory locations which will be included in the physical inventory. These are automatically loaded from the INV Control record and cannot be changed in this procedure.

Last Status Message Contains the last status message generated by the program.

Last Status Date The date on which the last status message was generated.

Last Status Time The time at which the last status message was generated.

Version 8.10.57