# Receipts Entry (RECEIPTS.E)

Read Time: 5 minute(s)

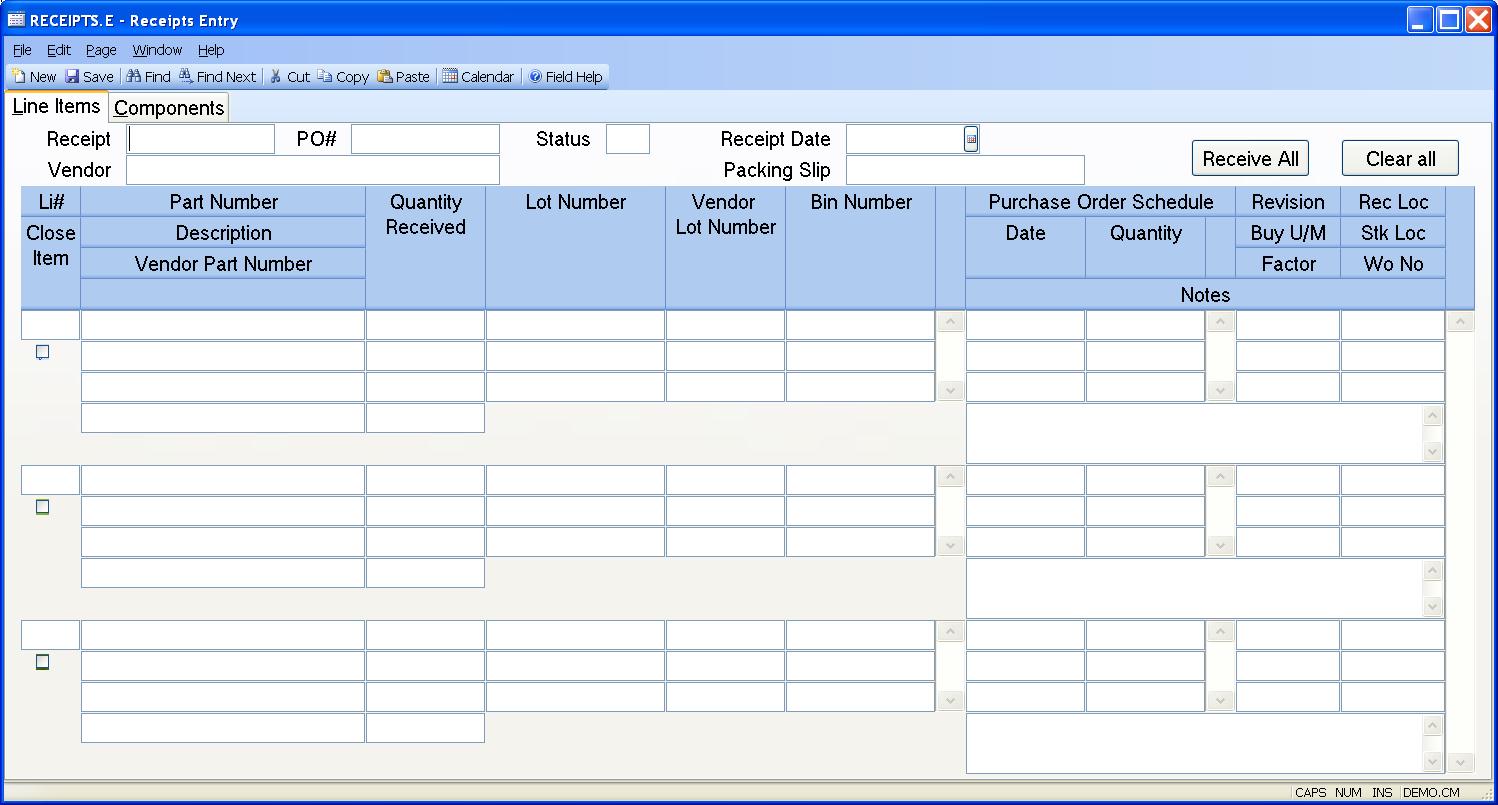

# Line Items

Receipt ID The receipt ID is assigned by the system and is made up of the purchase order number followed by a dash (-), followed by a sequential number which is maintained in the purchase order record. If you are creating a new receipt you should leave this prompt blank. If you want to make a change to an existing receipt you should enter the full receipt ID.

PO# Enter the purchase order number against which this receipt is being made.

Status The status field contains the current status of the receipt record.

It will display one of the following codes:

N - The items have not been received (pending receipt).

R - The items have been received.

P - The receipt has been posted and the accounts payable record has been

created.

If the status code is not already set to "P" then the user may enter the code "N" for new, or "R" for received. The "N" status sets the receipt as a new receipt and does not create any inventory transactions. The "R" status will confirm the receipt by creating inventory transactions and will then be posted the next time RECEIPTS.P1 procedure is run. Once the status has been set to "R" and the record has been filed, you may not reset the status to "N" or make any changes to the receipt.

Vendor Contains the name of the vendor associated with the purchase order. This data is loaded from the vendor record and may not be changed.

Receipt Date Enter the date on which this material was actually received.

Pack Slip Enter the packing slip number associated with the materials received.

Item Contains the purchase order line item number of the item you are receiving. This data is preloaded when you enter the purchase order number.

Receipt Qty Enter the quantity to be received. If this item is either lot or bin controlled, enter the quantity associated with each lot or bin. If it is neither then enter the entire receipt quantity for this line. If you did not receive anything on the associated item then leave this field blank.

Lot No If the item being received is lot controlled then you may assign the lot number in this field. If a lot number is not assigned and the part is lot controlled then the system will assign a number automatically when the record is filed.

Vendor Lot No If the vendor has specified a lot number for the items received you may record the vendor lot number in this field.

Bin Number Enter the bin number into which this material is being placed. Entry will only be allowed if the inventory location is set to bin control.

LI Qty This is the total receipt quantity entered for the line item. It is the sum of the lot quantities, if there are multiple entries. It is for display only and cannot be changed.

Open Schedule Dates Displays all of the dates for which there is currently an open quantity of the associated item on the purchase order.

Open Quantities Displays the quantity open on the associated date.

Part Number Contains the internal part number of the item being received. It is displayed to help identify the correct line item and may not be changed.

1st line of Description The description of the part being received. This

information is displayed to

assist you in determining the correct line item. It may not be changed.

Vendor Part Number The number the vendor uses to identify the associated part number. This information is displayed to assist you in determining the correct line item. It may not be changed.

Notes Enter any pertinent line notes for this receipt. These notes will print on the traveller.

Revision The revision level ordered of the associated part number. This data is loaded by the system and may not be changed.

Buy UM The unit of measure in which the vendor ships the materials. The data is loaded by the system and may not be changed.

Factor The factor by which the quantity received is multiplied to obtain the quantity received in the internal unit of measure. For example, if the vendor ships you eggs by the dozen, but you stock eggs individually, the factor would be 12.

Receiving Loc The location into which the system will record the receipt of the materials. The on hand balance in this location for the part will increase by the amount received.

Stock Location This is the inventory location into which the materials are to be moved after they complete the inspection process. The movement from the receiving location into the stock location is done as a separate transaction.

WO.ID Contains the work order number the part will be received into if the receiving location is a work in process location, or the work order into which the parts are to be moved after being received.

Close Li If the quantity received is less than the quantity ordered and you wish to close the line item short, check this box. The order/scheduled quantity will be adjusted to match the receipt quantity. If, for example, the order quantity is 100 and you receive in 98, the order quantity will be changed to 98. If this receipt is reversed via receipts.e3 , the order quantity will not revert back to 100. A check mark will default into this box for you, if the "do not backorder po" field is checked in the po.control procedure. If this box is not checked the line item will be backordered.

Receive All Pressing this button will cause all of the open purchase order quantities to be defaulted into the quantity fields. At that point, changes could be made to the receipt quantity.

Clear all This button can be used to clear all quantities from the received quantity field.

Version 8.10.57